Bioinspired Manufacturing: Nature's Blueprint for Industrial Innovation

In an era of rapid technological advancement, manufacturers are turning to an unexpected source of inspiration: nature. Bioinspired manufacturing, a cutting-edge approach that mimics biological systems and processes, is revolutionizing industrial practices. This innovative methodology promises enhanced efficiency, sustainability, and resilience in manufacturing operations.

The fundamental premise is simple yet profound: nature has spent billions of years perfecting its designs through evolution. By emulating these designs, manufacturers can create more efficient, sustainable, and adaptable systems. From self-cleaning surfaces inspired by lotus leaves to energy-efficient building designs based on termite mounds, nature offers a vast repository of solutions waiting to be tapped.

Key Principles of Bioinspired Manufacturing

Bioinspired manufacturing encompasses several core principles that set it apart from traditional manufacturing approaches:

-

Adaptability: Natural systems are inherently adaptable, capable of responding to changing environmental conditions. Bioinspired manufacturing seeks to replicate this flexibility in industrial processes.

-

Efficiency: Nature operates on the principle of minimal energy expenditure. Bioinspired manufacturing aims to optimize resource use and minimize waste.

-

Resilience: Biological systems often have built-in redundancies and self-repair mechanisms. These features are being incorporated into manufacturing systems to enhance reliability and longevity.

-

Sustainability: Nature operates in closed loops, where waste from one process becomes input for another. Bioinspired manufacturing strives to emulate this circular economy model.

Applications in Modern Industry

The principles of bioinspired manufacturing are finding applications across various industrial sectors:

-

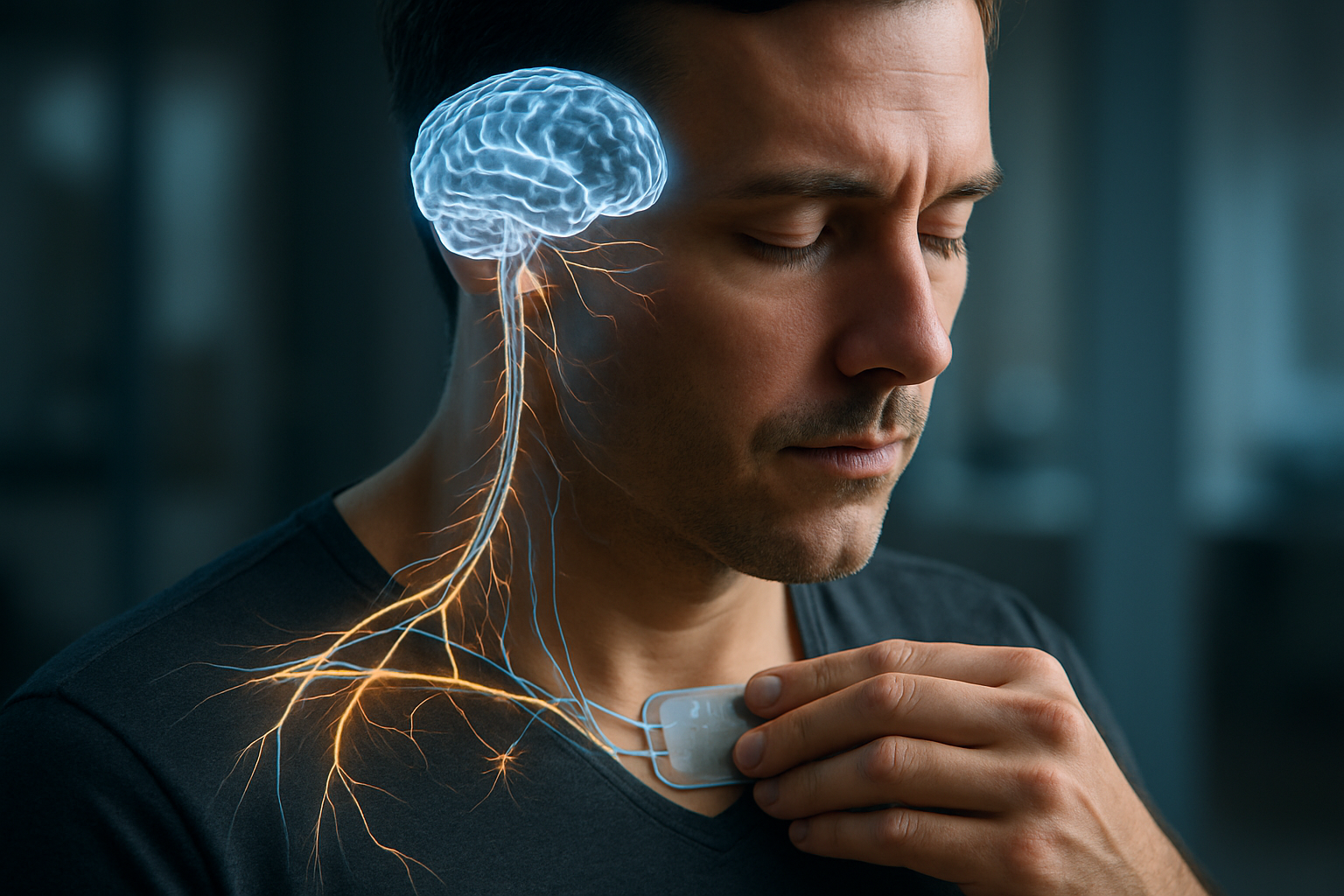

Materials Development: Researchers are developing self-healing materials inspired by human skin, which could significantly extend the lifespan of industrial equipment and reduce maintenance costs.

-

Process Optimization: The decentralized decision-making of ant colonies has inspired new approaches to supply chain management and production scheduling, leading to more efficient and flexible operations.

-

Energy Conservation: The structure of butterfly wings has inspired more efficient solar panels, while the aerodynamics of humpback whale flippers have led to more energy-efficient wind turbine designs.

-

Waste Reduction: The closed-loop systems found in ecosystems are inspiring innovative waste management solutions in manufacturing, where byproducts from one process become raw materials for another.

Challenges and Future Prospects

While bioinspired manufacturing holds immense promise, it’s not without challenges. Translating biological principles into industrial applications often requires significant research and development. Moreover, existing manufacturing infrastructure and processes may need substantial modifications to incorporate bioinspired approaches.

However, the potential benefits far outweigh these challenges. As environmental concerns become increasingly pressing, bioinspired manufacturing offers a path towards more sustainable industrial practices. Furthermore, the adaptability inherent in biological systems could help industries become more resilient in the face of unpredictable market conditions and supply chain disruptions.

Looking ahead, the convergence of bioinspired manufacturing with other emerging technologies like artificial intelligence and advanced robotics could lead to truly revolutionary manufacturing systems. These “smart factories” could adapt to changing conditions in real-time, optimize their own processes, and even evolve new solutions to unforeseen challenges.

Implementing Bioinspired Manufacturing: Practical Insights

• Start small: Begin by identifying specific processes or products that could benefit from bioinspired solutions.

• Collaborate: Partner with biologists and environmental scientists to gain deeper insights into natural systems.

• Invest in R&D: Allocate resources for researching and developing bioinspired technologies tailored to your industry.

• Educate your team: Foster a culture of biomimicry by training employees to look to nature for innovative solutions.

• Think long-term: While initial investments may be high, the long-term benefits of efficiency and sustainability can provide significant returns.

As we face increasingly complex industrial challenges, nature’s 3.8 billion years of R&D offer a treasure trove of tried-and-tested solutions. By embracing bioinspired manufacturing, industries can not only enhance their operational efficiency but also contribute to a more sustainable and resilient future. The key lies in viewing nature not as a resource to be exploited, but as a mentor from which we can learn and innovate.